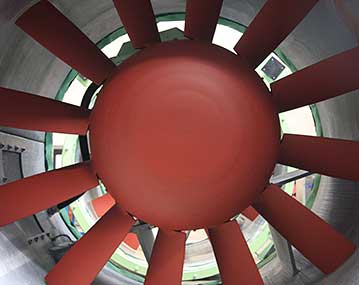

Axial Fans

Our axial fans are used in several applications, including for the offshore, marine & shipbuilding and mining industries. There too, our axial fans are ideal for high flow rates and process conditions in which high efficiency is required.

- Flow rates up to 1,000,000 m3/h (588,578 ft3/min)

- High efficiency

- Fixed & adjustable pitch

- Single stage

- Special materials

- ISO 9001

- Materials: aluminum and stainless steel.

- Welding: respecting ASME, AWS, EN norms with virtually no limit to the type of material.

- Impellers: in cast, extruded or fabricated construction

We can machine shafts up to 30 tons, impellers up to 5 m (16’) in diameter and shrink up to 12 m x 5 m (39’ x 16’). Few other companies in Europe and in the world can offer this.

- Non-destructive tests: UT, MP, dye penetrant test

- Rotor balancing: ISO 1940, DIN 2060

- Test room capacity: 2000 kW VFD, up to 11 kV transformer

- Performance – aeraulic tests: AMCA 210, ASME PTC11, BS 848

- Thermal & acoustic test facilities

- Pressure tests, hot gas tests, shock tests and more

We can test fans using ducts of up to 3 m (10’), balance up to 5 m (16’) diameter and up to 40 tons (88185 lbs), run tests at full speed for fans up to 5 MW (6705 hp), and complete unit tests for motor ratings of up to 5 MW (6705 hp), with an 13.8 kV supply.

Industries

Marine

Shipbuilding

Offshore

Mining

Applications

Ventilation

Compressor room

Evaporators’ room

Purifier room (combustion & cooling air)

Diesel generator (combustion air)

Electric propulsion motor

Battery room

Heat exchangers

Industries

Marine

Shipbuilding

Offshore

Mining

Applications

Ventilation

Compressor room

Evaporators’ room

Purifier room (combustion & cooling air)

Diesel generator (combustion air)

Electric propulsion motor

Battery room

Heat exchangers

Fans, Blowers & Compressors Case Studies

Engineering Fan Systems for a Hydrogen Reformer at a Photovoltaic Power Plant in Bulgaria

Boldrocchi was hired to provide the fan systems for a hydrogen reformer at a photovoltaic power plant (PPP) near Burgas, Bulgaria. Boldrocchi designed, manufactured and tested the combustion air and flue gas fan and its system for this project. It involved a 700 kW induced draft fan and the fan machinery train. What was most interesting about this project was its special construction on spring isolators. The entire system had to be designed to be mounted on top of the reformer’s steel structure.

Revamping a Fan in Mexico: Performance Up, Costs Down

In 2016, Boldrocchi was awarded a contract to revamp a kiln fan at a cement plant in Tepetzingo. Plant officials were looking for a major performance increase but had a limited budget. Our kiln fan revamp increased the fan’s performance by 40% while saving 30% in costs. To further reduce costs, we designed a partial casing replacement to allow the client to keep most of the existing casing.

Boldrocchi Builds Special Test Facility for Turkish Order of Multiple Blowers

Boldrocchi engineered and manufactured a number of systems for a refinery in Izmir, Turkey. Among the systems: a CCR Chlorination Blower used in petrochemical chlorination and catalyst regeneration processes.

In order to satisfy the process requirements, Boldrocchi built a special test facility to check the blower’s performance at various temperatures, up to 600°C (1112°F). Boldrocchi also designed and fabricated a cooler blower, a combustion air blower, a recycle gas blower, a fines removal system and a regeneration blower.