Heavy-Duty Process Dampers

Dampers may seem like simple pieces of equipment, but when they won’t open or close one realizes how important they are. In our experience, many take dampers for granted – which has led some to make major mistakes in contracting inexpensive and inexperienced companies to produce their dampers, often resulting in unexpected and costly production stoppages.

Advantages

We invite clients or their representatives to our testing facilities near Milan, Italy, to inspect their damper / diverter systems.

Types

We offer all types of dampers, including on/off, modulating and zero leakage dampers. All of our dampers are offered in a variety of materials, depending on the use, operational temperature & corrosive elements.

Diverter dampers

- Geometrical sealing degree is greater than 99.95%

- Sealing pressure > 500 mm w.g.

- Different actuator types available: hydraulic, electric, pneumatic

- Reduced maintenance

- Easy transportation and assembly

- Quick installation for passage from single cycle to combined cycle

Applications:

- HRSG isolation

- Gas turbine bypass systems

Tandem dampers

- Ensure 100% gas tightness (zero leakage) with sealing air system

- Fast closing/opening times

- Available with parallel or opposed blade configurations for improved flow control

- Sealing air inlet nozzle on top with a distributor-type profile, achieving uniform air flow & equalized/stable air sealing pressure value

- Can be designed with inner insulation

- Can be assembled in workshop to reduce installation times on site

Applications:

- Fan isolation

- HRSG isolation

- Stack isolation

- Gas turbine by-pass system

Multi-louver dampers

- Ensure 100% gas tightness (zero leakage) with sealing air system

- Fast closing/opening times

- Available with parallel or opposed blade configurations for improved flow control

- Opposed blade louver dampers provide superior control of static pressure & volume for rectangular duct applications

- Increasing the number of opposed blades (2-3+), generally improves flow control characteristics

- Single surface/air-foil configurations available

- Can be designed with inner insulation

- Can be assembled in workshop to reduce installation times on site

Applications:

- Fans modulation

- HRSG isolation and control

- Gas turbine by-pass system

Butterfly dampers

- Provide excellent control of static pressure & volume in mid-range

- Broad application versatility by using a center-mounted rotating blade for modulating applications

- Ensure 99-99.9 % gas tightness & 100% with sealing air pressure system

- Fast closing/opening times

- Available on parallel or opposed blade configurations for improved flow control

- Opposed blade louver dampers provide superior control of static pressure & volume for rectangular duct applications

- Increasing the number of opposed blades (2-3+), generally improves flow control characteristics

Applications:

- Fans modulation

- HRSG isolation

- Gas turbine by-pass systems

Stack dampers

- Ensure 99 – 99.5% gas tightness

- Prevent heat loss from HRSG & prevents rain from entering HRSG

- Designed for isolation/closure of HRSG exhaust & bypass stacks

- Automatic pressure relief assured by offset shafts & adjustment counter weights

- Available on opposed blade configurations

Applications:

- HRSG isolation stack

- By-pass isolation stack

Gas distributor dampers

- Alternative to a flap diverter

- Multi-louver dampers can be built into a T-duct & linked to provide effective inlet/bypass solution

- Sealed air system can be added to provide 100% tightness (zero leakage)

- Sealing air inlet nozzle on top with a distributor-type profile, achieving uniform air flow & equalized/stable air sealing pressure value

- Single/double blade surface configurations that meet the most severe operating conditions

Applications:

- Power generation

- HRSG isolation/modulation

- Stack isolation/modulation

- Gas turbine by-pass system

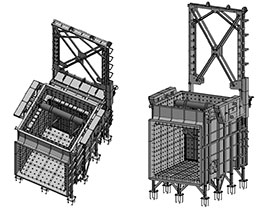

Guillotine dampers

- Ideal where positive isolation is required for routine maintenance and/or personnel safety

- Can be installed in a short length of ductwork

- Blade normally out of the gas stream

- Low pressure drop when blade fully opened

- Round, rectangular or square

- Internal or external insulation

- Bolted cover prevents leakages & prevents erratic/quick opening

Applications:

- HRSG isolation

- Stack isolation

- Offshore and oil & gas

- Air pollution control/environmental solutions

- Cement & metallurgical

- General industrial

Heavy-Duty Process Damper Case Studies

Delivering Diverter Damper Systems to Nigeria Within a Mere 4 Months

In 2016, Boldrocchi was awarded a contract to supply eight (8) diverter damper systems for six gas turbines, to be installed at a refinery in Lekki, Nigeria. The goals: achieve reduced wear & extended operational life. Thanks to our large in-house facilities, all 8 were assembled at once. They were then tested in-house in the presence of the customer’s inspectors. Turnaround was very short – at least for the first two – and Boldrocchi delivered within a mere 4 months.

Helping Close an Open-Cycle Circuit on a Gas Turbine in Oman

Boldrocchi helped close an existing open cycle circuit on a GE turbine in Amal. We designed four various dampers and diverters and had them made on-site, constantly supervising fabrication. Installation of the diverter, also supervised by Boldrocchi, was a significant challenge: the diverter measuring 5.2 x 5.2 m (17’ x 17’) had to be fit into the existing circuit with a mere 20 cm (8”) clearance!

Boldrocchi Successfully Tests 7m X 7m Diverter for Gas Turbines

Boldrocchi welcomed over 30 customers from some of the largest OEMs to its in-house testing facilities near Milan, Italy in 2018, for the functional testing of an enormous 7m X 7m (23’ X 23’) diverter damper. The gas turbine diverter, one of three delivered to the client, not only offers extreme capacity, but surpasses the norm in terms of geometrical sealing, sealing pressure and closing time, while reducing maintenance and easing transportation and assembly.