Products: Air Pollution Control, Dust Removal

Industry: Power, Waste-to-Energy & Biomass

Location: Jazan, Saudi Arabia

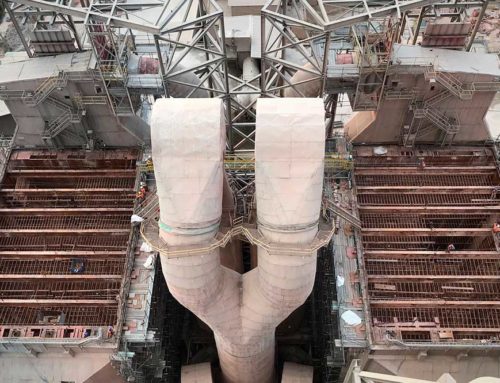

Boldrocchi designed and provided 8 ceramic candle filters with cyclones to the Jazan Integrated Gasification Combined Cycle plant in Saudi Arabia. High temperature filtration using ceramic candles was chosen due to the high temperature of the flue gas (over 250°C). Boldrocchi is one of the few companies in the world with experience implementing ceramic filters.

At this IGCC plant, a solid or semi-solid fuel is converted into a synthetic gas (syngas) that can be used as primary fuel in a combined cycle power plant. Multiple special furnaces are used to burn carbon residuals from the gasification process soot and to recover saleable dust with a high content of chrome and vanadium. Together, Boldrocchi’s cyclones (which act as a dust pre-separator) and ceramic candle filters, filter the dust – with the high content of heavy metals – from the furnaces’ flue gas before being released into the atmosphere. Ceramic elements are ideal as filtering media here because of the high temperature of the flue gas: continuously over 250°C.

Boldrocchi’s ceramic candle filter system easily met all main requirements:

- Continuous operating temperature: 250°C

- Peak Temperature (up to 48h): 350°C

- Required dust emissions: < 20mg/Nm3

- Maximum pressure drop: 20 mbar

Ceramic candle filters could also be used in such a plant to filter the flue gas from the syngas treatment. This would offer optimal filtering performance without the typical heat waste due to the wet treatment system. In addition, the collected dust from the ceramic candle filter would not require any further treatment for drying.

Ceramic candle filters reduce OPEX: they require less energy, fewer cleaning cycles and reduced downtime. These filters offer any benefits: they provide optimal filtration efficiency while withstanding high operating temperatures and are particularly useful when looking to increase heat recovery and/or comply with stringent emission regulations. Performance-wise, they are among the best on the market, offering emissions reductions of up to 1 mg/Nm3 and easily filtering fine particulates, by far complying with the most stringent emission regulations.

To learn more about this project, read our article “Ceramic Saviour” in Hydrocarbon Engineering, April 2017.