Products: Air Pollution Control, Dust Removal

Industry: Cement & Lime

Location: Kodla, India

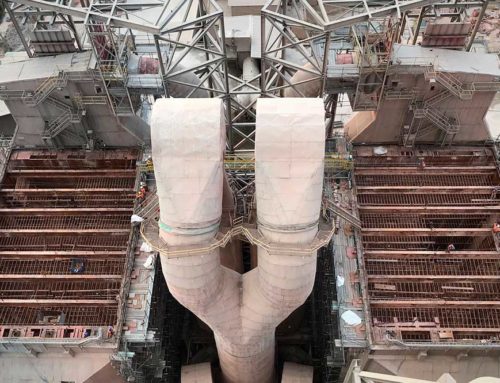

In October 2017, Boldrocchi was contracted to engineer and manufacture 46 customized nuisance filters for the Karnataka Cement Plant in Kodla, India with an extremely tight delivery timeline: four months after contract signing.

Boldrocchi analysed the various dedusting requirements and tailor-made each of the nuisance filters to attain the customer’s overall performance objectives, including a low pressure drop and the required outlet emissions. The filters were designed to handle flow rates ranging from 5,000 m3/hr to 50,000 m3/hr. Each nuisance filter was engineered to handle dust loads of up to 50 mg/m3. Every one of the 46 filters also had to be customized to process dust emitted from various materials, such as clinker, coal, flyash, gypsum and cement.

Challenging Deadlines

The success of this contract not only came from meeting all customer objectives in terms of nuisance filter performance, but also from Boldrocchi’s rapidity, on-time delivery and planning. Indeed, the timeline to design, manufacture and produce all 46 nuisance filters was an incredible four months! Although an evident challenge, all filters were delivered on schedule. In addition, all nuisance filters with flow rates under 40,000 m3/hr were assembled in-house at Boldrocchi facilities and delivered fully assembled, which greatly helped the customer keep their erection timelines on-site making installation was very quick.

Shree Cement fully commissioned this 3Mt/yr integrated plant in January 2019, although the cement grinding mill was commissioned in June 2018 and the cement mill and the clinker line were commissioned at the same time in late December 2018.