Dust Removal

Our dust removal technologies surpass all global particle matter (PM) requirements. Our solutions can achieve practically zero emissions: 0.1 mg/Nm3 (0.06 gr/ft3) (WTE applications) and we also offer systems that reduce not only PM10 and PM2.5, but PM0.1 a.k.a. ultrafine particles. Indeed, we continue to invest in our R&D to remain ahead of legislation, ensuring that you’re covered for years to come.

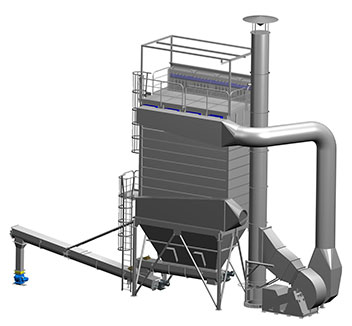

Fabric Filters / Baghouses

We can design and produce fabric filters (baghouses/bag filters) for any industry, any application and any process condition as we tailor-make each one. Our fabric filters offer 99.9% efficiency, blocking even the smallest particulate matter (PM) (micro-pollutants).

Read about our Fabric Filter installations

Depending on the design details and fabric used, our fabric filters can be designed and manufactured to:

- Block particulate matter (PM), even ultra-fine particulates (< 1mm)

- Tackle high dust concentrations (> 1000 mg/Nm3)

- Filter flow rates from 1,000 m3/hr to over 3 million m3/hr (600 cfm to over 1.8 million cfm)

- Undertake dust loads of over 1,000 g/Nm3 (0.035 oz to 35 oz)

- Withstand high temperatures ≤ 250°C (482°F)

- Resist aggressive chemicals such as acid gases, sulfur oxides & chloride

- Minimize pressure losses

- Fit in the required footprint

Types

Pulse-Jet – Low Dust

Pulse-Jet – High Dust

Explosion-Proof

Multi-Source Fabric Filter Solutions

Ceramic Candle Filters (High Temperature Filtration)

Filtration using ceramic filters is a technology gaining increasing interest and Boldrocchi is one of the few companies in the world with experience implementing it. High temperature filtration provides optimal filtration efficiency while withstanding high operating temperatures and is particularly useful when looking to increase heat recovery and/or comply with stringent emission regulations. What’s more, the use of ceramic filters reduces OPEX as they require less energy, fewer cleaning cycles and reduced downtime while foregoing the need for cooling systems.

Read about our experience with Ceramic Candle Filters

- High heat tolerance: withstands temperatures of ≤ 800°C (1470°F), peaks of ≤ 1000°C (1830°F)

- High efficiency: emission levels ≤ 1 mg/Nm3 (gr/ft3) reached, easily handling fine dust

- High chemical resistance: can be used with wide range of common reagents & sorbents

- 100% spark resistance: non-flammable, unlike traditional filter media

- High permeability: translates into low pressure drop

- Environmentally friendly & safe: non-carcinogenic

- Gas cooling not required: no water consumption/additional dilution of the gas

- Useful heat generation: possible heat recovery after the filter & avoids need to re-heat the gas for tail-end SCR

- Easily integrated into existing plant: same general design, gas distribution, cleaning system as traditional fabric filter technology

- Eliminates need for filter bag cages: ceramic filters made of high density self-supporting material

- Lightweight: reduces weight on bag filter’s cell

Research

Boldrocchi has been studying the efficacy of ceramic candle filters laced with a catalytic material. An integrated catalyst would allow customers to forego a DeNOX reactor.

Dry Electrostatic Precipitators (ESPs)

Electrostatic precipitators (ESPs) continue to be excellent devices to control particulate emissions in several industries, including fumes from electricity-generating utilities (coal- and oil-fired) and catalyst collection from fluidized bed catalytic cracker units in oil refineries to name just two. We have significant experience dealing with ESPs in the cement industry as well, most often to refurbish or retrofit existing ESPs. Boldrocchi can also convert ESPs: use the external casing and some parts but transform the system into a fabric filter or hybrid filter. Retrofit, upgrade and conversion solutions are all lower CAPEX solutions.

Read about our ESP installations

- Treat gas volumes from several m3/s (hundreds of thousands of ACFM) to 1,180 m3/s (2.5 million ACFM) in the largest coal-fired boiler applications

- High temperature functionality – works over 400°C (752°F)

- Excellent capture efficiency on small particles

- Low energy consumption

- Modest maintenance requirements – stable and reliable service for many years

- Proprietary design & in-house manufacturing of rigid electrodes that are individually suspended at the top, yet unattached at the bottom to allow free thermal expansion

Hybrid Filters

Hybrid filters offer high efficacy in dust removal. Hybrid filters are both an electrostatic precipitator (ESP) and a fabric filter in one system. The dust is first collected by the ESP section, and by the time the gas goes into the fabric filter portion, dust is greatly reduced.

Read about our experience with Hybrid Filters

- Great performance: the smallest micro particles – the most dangerous for humans and animals – are captured and disposed of.

- Lifetime and efficiency: the fabric filter portion undergoes less stress and therefore performs exceptionally for a longer amount of time.

- Reduced footprint in greenfield projects: by removing the majority of dust in the ESP section we can increase the filtration velocity and decrease the number of bags, allowing customers to save space.

- Reduces CAPEX in revamp projects: more parts of the existing system can be re-used (although OPEX can be slightly higher).

- Compressed air savings: fewer cleaning cycles are required

- Reduced energy costs: a smaller ID fan is required in a hybrid (ID fans help remove dust caked-on the filter bags, which in a hybrid filter, the ESP portion does.)

Nuisance Filters

Many clients know they need dust suppression, but don’t know exactly what they need. Others have space constraints and need off-sizes or strange shapes. Boldrocchi’s air pollution control specialists are experts in studying your process parameters, dust suppression goals and space constraints – they’ll go on-site if they have to – to design a customized solution that will achieve (or surpass) objectives and offer reliability for years to come.

Read about our Nuisance Filter installations

- Low CAPEX

- Reduces OPEX

- Lowers maintenance costs of entire dust removal system

- Lower replacement costs

- Effective particulate reduction to 2-20 mg/Nm3, depending on client’s goal

- Further protects the environment

- Ensures workers’ health and safety

- Sizes from 1 m x 1 m (3’ x 3’) to 3 m x 6 m (10’ x 20’)

Cyclones & Multi-Cyclones

Adding cyclones or multi-cyclones can be a cost-effective strategy. They use centrifugal action to separate suspended particulates and collect them in a hopper. Cyclones are particularly effective with particles of a certain size and density, able to reduce dust (by weight) by up to 95%, or more if using multi-cyclones.

Read about our expertise worldwide

- ≤ 95% efficiency in dust removal (cyclones)

- ≥ 95% efficiency in dust removal (multi-cyclones)

- Sizes ranging from 500 mm to 5 m (2’ to 17’) in diameter (cyclones)

- Variety of materials available

- Virtually maintenance-free

- Easily added to existing systems

- Used as a pre-separator, cyclones increase the service life of higher efficacy dust control systems by taking-on some of the dust load

Applications

Cyclones can be used for various applications: as dust pre-separators, spark arrestors or to enhance flue gas treatment. They are also well suited for erosion control upstream of fans and finish filtration. Our multi-cyclones are several abrasion-resistant cast-iron tubes in a casing to increase cyclone efficiency.

Dust Removal Scrubbers

There are numerous kinds of scrubbers and Boldrocchi offers most of them. In terms of dust removal, Boldrocchi offers a wet scrubber or “Venturi” scrubber that removes dust particles – this one for rather light applications. These wet scrubbers use only water with no reagent to remove particulate matter (PM). These devices are relatively small compared to our other dust removal solutions, at roughly two stories high.

Read about our experience with APC

Industries & Applications

Pulp & paper

Steel

Oil & Gas

Biomass applications, such as with sugar cane

Circulating Dry Scrubbers

Boldrocchi offers Circulating Dry Scrubbers as well. Our specialized team will study your operation’s process parameters and objectives and recommend which to choose. Our engineers tailor each scrubber in order to ensure your desired efficiency is reached.

Combustion Chambers / Drop-Out Boxes

Combustion chambers (or “drop-out boxes”) are dust pre-separation devices that protect the more efficient filtration device (often a fabric filter) from possible abrasion and sparks, increasing the lifetime of the main filtration device. These combustion chambers are common to de-dust electric arc furnaces, for example, in the steel industry.

Read about our air pollution control expertise